H4F33Z

Active Member

Considering Metrolinx interests... and the private companies' interests... Only the train bridge probably

-Mark Richardson, technical lead with HousingNowTO"If we give people alternative ways to get onto the Danforth, we're going to have better housing, for transit, for retail. And we're about to spend billions of dollars putting an underground Ontario Line at Pape and Danforth — it's not going to be eight storeys above a billion-dollars'-worth of infrastructure," he said. "It's going to look like Main and Danforth — not Pape and Danforth."

Today is proof that the Ontario line SHOULD be built to TTC specifications AND there should be a wye at Pape at the very least. Line 1 experienced a catastrophic incident that would have been made significantly worse had the T1s not been able to enter Line 1. In the event that the Ontario Line goes out of service for any reason and the yard is blocked off from another area of the line, trains from Greenwood (or eventually Wilson and Davisville when the line is extended to Sheppard) would be able to be deployed on the line.

Which block at Pape and Danforth do you want to demolish for the wye? North-East or North-West? I suppose there are fewer historic landmarks in the North-East block, but it's not going to be pretty or popular.

If you want a wye, put in a connection between the Ontario line and Greenwood yard along/under the rail corridor. The Greenwood yard abuts the rails corridor.

Today is proof that the Ontario line SHOULD be built to TTC specifications AND there should be a wye at Pape at the very least.

I would anticipate that adding a wye track to an active subway line would either require substantial service disruption (not really feasible), or weekend work meaning it will take an excessive amount of time. Think of how long trackwork takes using weekend shutdowns on the current lines. Wye construction could take a decade at that rate.

Must be new to this thread?

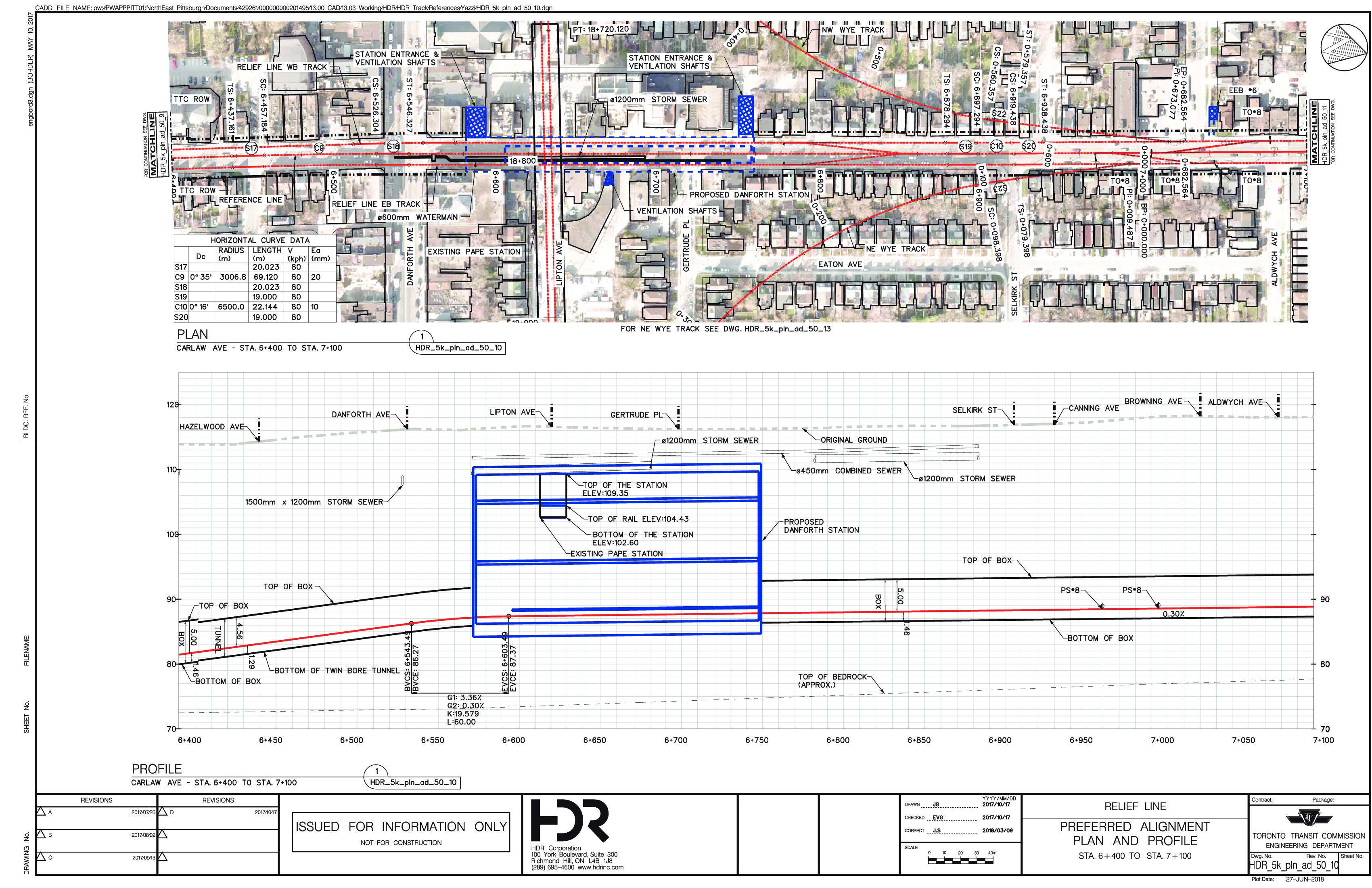

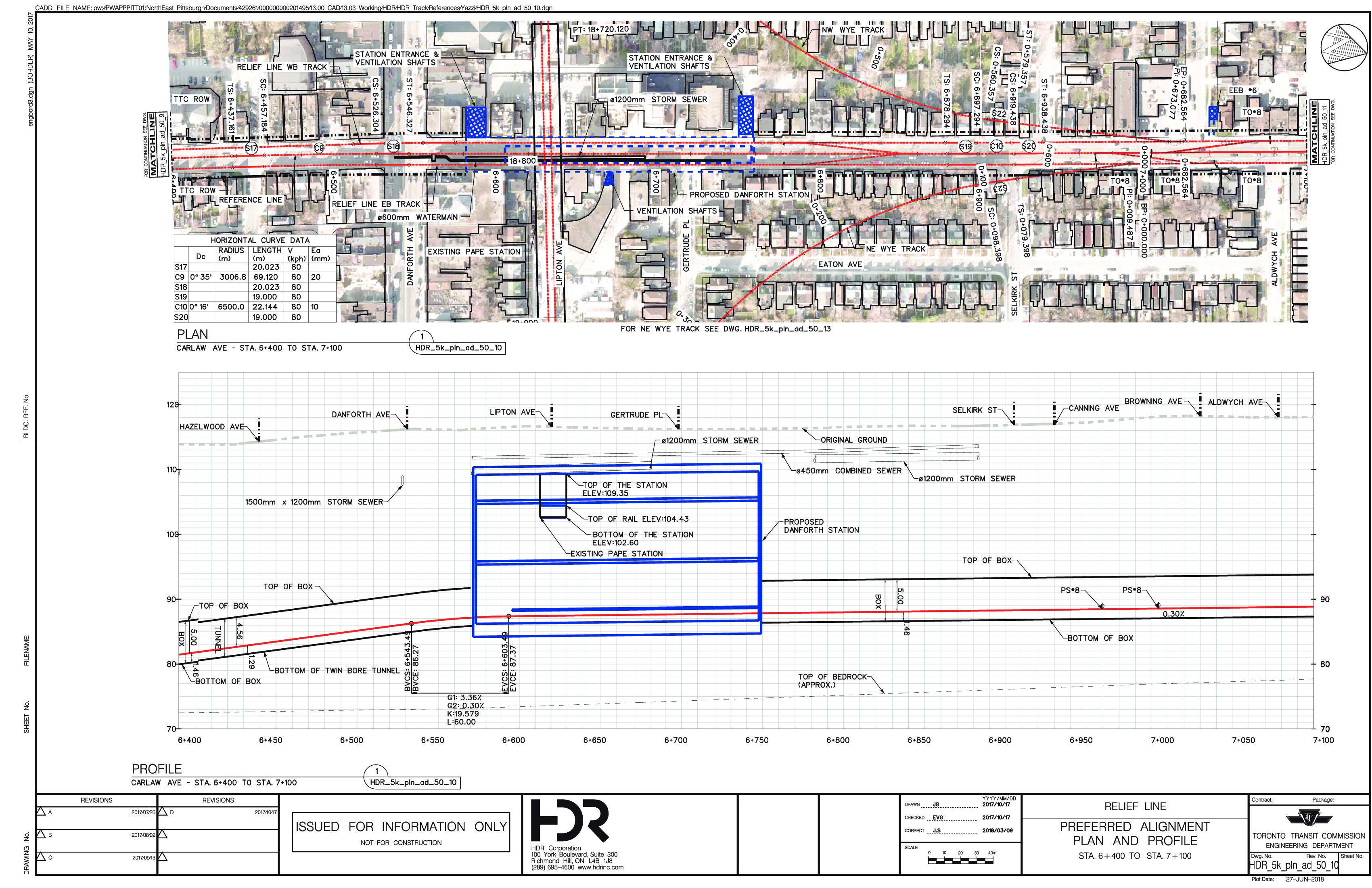

Go and look at http://www.east-toronto.ca/downtown-relief-line-update/ to see what the plans were before Doug Ford showed up with his napkins and crayons.

Instead of ADDING to the existing plans, he basically threw those plans away and started all over again with his own plans

Interesting, thanks. That's a lot of property acquisition for a cut-and-cover wye.

Mistake on the diagram: Muriel Ave is mislabeled as Eaton Ave. They're off by one street.

It's been done in the past, and it certainly didn't take that long. What makes you think it would take substantially longer this time around?

Dan

I thought it was pretty much concluded awhile ago that between Carlaw and East Harbour it will be elevated above the rail corridor, one side. With the guideway roughly taking up the equivalent of one track on the expanded corridor. And the guideway wouldn't use regular T columns, but an inverted L, sort of cantilevered and allowing one mainline track below. The two station structures will probably straddle a bit outside the rail corridor though.

The real estate aspect seems a bit unfortunate with the Leslieville station. Obviously the better bet for a station would be Carlaw/Queen, not DeGrassi 500m away with no N/S transit route.

Since it looks like there will be a separate "Ontario Line" bridge to carry trains from Pape Avenue to Thorncliffe Park, what about including a bicycle & pedestrian bridge within the infrastructure?

That's probably a no brainer if there's no existing alternative.

Funding for the "add-on" would have to come from a separate source, of course.

The equivalent of 710 million fares, by my count. Damn, there must be a lot of people not evading their fares for the TTC to have such a revenue problem. Wait...

That was built using cast-in-place concrete. were those joints created periodically to allow for shrinkage of the concrete to occur at these joints, instead of creates cracks in the concrete. There is a recess shown which likely had a gasket of some sorts between where the next segment is cast, to seal for waterLine 2 cut and cover sections, as far as I am aware, are made from concrete sections. These are quite easy to see in the photo below:

View attachment 230846

(Source: A view of the construction of the BLOOR-DANFORTH subway through Christie Pits, Transit Toronto)

The way the concrete sections are assembled, there appears to be no interlock between each segment as shown below:

View attachment 230847

(Source: Happy birthday to the Bloor-Danforth subway, CBC News)

As there's no interlock between the segments, any differential displacement could cause substantial problems to the rail track. These are likely not operating like a stiff beam but instead a collection of segmented pipe. Segmented concrete pipe is quite sensitive to differential settlements. If there's excessive cant or twist in the rails, the line could be entirely shut down until the problem could be remediated.

TBM tunneling, SEM caverns, and cut-and-cover all have the ability to introduce settlement. Linearly passing under the sections may not cause a large disturbance, but coming in from either side certainly could. You'd have to very closely monitor ground movement regardless of the method chosen. It's likely that ground freezing would need to be employed to ensure minimal movement. If the process is going to take place over several seasons, that needs to be taken into account. To avoid any tilt, both incoming wye tracks would have to be perfectly in sync. Even the small staging difference of the TBM advancement needed to be taken into account while passing under the station, and TBMs have quite low and predictable settlement curves.

You certainly aren't going to launch a TBM from either side of the wye to meet up at Line 2, so it would be between SEM and/or cut-and-cover. You'd need to remove a substantial amount of housing to perform cut-and-cover, while SEM would be considerably more risky. If you're trying to minimize the size of the cut-and-cover boxes, irregular shaped boxes come with considerable settlement, and it is often irregular and unpredictable.

All the prep work and monitoring required to pull off this kind of maneuver on an active subway line would tkae a considerable amount of time.

There is no way that any of the mining methods for connecting the wyes could be carried out during passenger service. What company would be willing to take on that level of liability, when cant in the rail could result in derailing a passenger filled subway?

Are you going to perform ground freezing indefinitely while performing a large cut-and-cover in a busy intersection and only be able to do work nightly or on weekends? How will you manage all the relocates during the project? It's much harder to just dig around things when you're in tight quarters like that. That level of complexity, in my mind, would require at least early nightly shut downs, not just weekend work. 10 years may be longer, but I would put it in that ballpark. There is a substantial amount of work that needs to be done around the site, not just linking up the rails.

EDIT: Just wanted to clarify, when I say no interlock, I realize there is a lip on each segment that connects to the next. What I mean by this is there is no tie in or dowel holding the segments together. the joint has zero tensile strength, making it very easy to shift from differential settlement. Examples of axial pullout and flexural pullout, both common issues in segmented pipe:

View attachment 230851

View attachment 230852

(Source: xDisp Help Guide, Oasys)