We recently sat down with Carlos de Oliveira and Michael Gray, co-founders of the structural engineering company CastConnex, to talk about why their casted connections are so innovative and how their work led to the amazing delta frames in the new Queen Richmond Centre West building.

We interview Carlos (left) and Micheal as the co-founders of CastConnex, image by Jack Landau

We interview Carlos (left) and Micheal as the co-founders of CastConnex, image by Jack Landau

Edvard: Can you describe the genesis of the company and where the idea came from?

Carlos: In 2004 I started a masters thesis at the University of Toronto with professors Packer and Christopoulos. We started getting into the research in 2005, and at that time Micheal started what would become his doctoral work with the same supervisors. Ultimately the four of us started looking into casting manufacturing as a means to address various technical challenges in the design, fabrication and construction of certain types of connections in buildings and we honed in on earthquake resistant connections because they represent a design and constructional challenge. We identified that the freeform geometry that casting manufacturing allows could address some of these technical challenges in a unique way; monolithic, components could be shaped to mimic the natural flow of forces in the part, putting material where it should be.

In addition we found that with clever casting design, we could actually save other costs beyond fabrication, for example our cast connector for braced frame buildings eliminates the need to field weld braces. This in fact speeds up construction and reduces costs in the field and improves quality all at the same time.

The High Strength Connectors welded in the shop instead of on site, image courtesy of CastConnex

The High Strength Connectors welded in the shop instead of on site, image courtesy of CastConnex

While castings have been used in buildings all over the world for quite some time, we started cluing in on all these neat things you could achieve and do with steel castings, which wasn’t really done before.

E: Steel castings?

C: Steel castings have been used in construction since about the late 70s and early 80s, particularly in Europe and Asia, and now finally in North America. But all those applications were like the Queen Richmond Centre West, where a custom casting is designed for a specific project, whereas we put a North American spin on casting use, sort of like the Model T approach by mass-producing. We researched connections that we could standardize and mass-produce with casting; connections that were challenging technically but also show up frequently in the construction of a variety of building types.

So that was the research that Michael and I were doing with Packer and Christopoulos; my research was simpler than Michael’s, it was just to solve these connection challenges for bracing in concentrically braced frames.

E: Were you using the large brace testing setup in the Sanford Fleming U of T structural lab?

Micheal: No, actually these tests predated the construction of that testing frame.

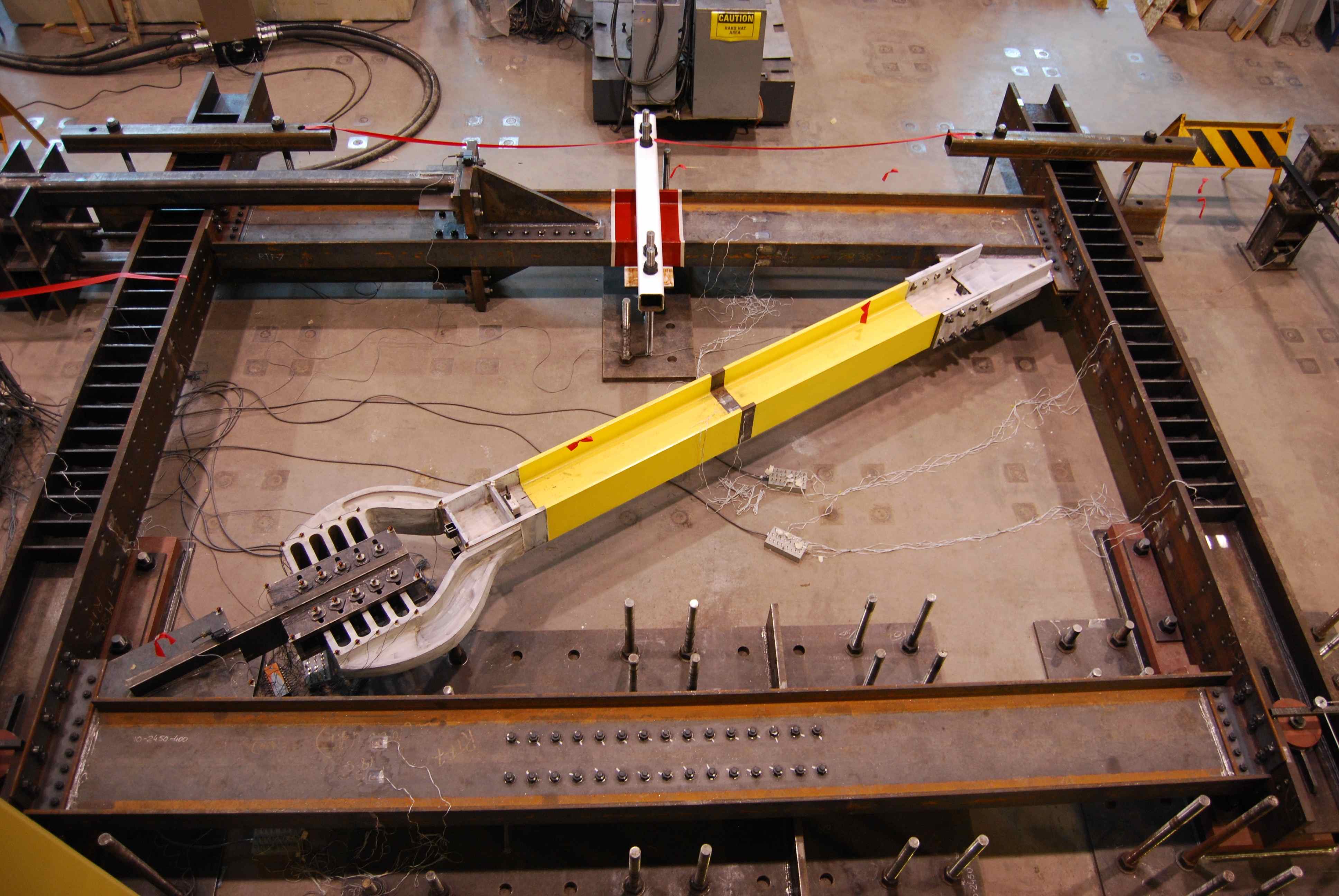

C: We were just using the MTS for very short braces. Then we actually used the Baldwin testing machine in tension. So my Master’s thesis resulted in the development of what is now our company’s high strength connector line of products. Then we founded CastConnex in 2007, and Micheal continued his doctoral work at the University of Toronto and developed what are now the company’s scorpion yielding connectors (images below). They represent an extension of the work I was doing, into the material's non-linear range. The connectors I developed are intended to remain predominantly elastic and they focus inelasticity and yielding into the brace member in a building.

Scorpion Yielding Connector in the test frame at the University of Toronto, image courtesy of CastConnex

Scorpion Yielding Connector in the test frame at the University of Toronto, image courtesy of CastConnex

E: But in the scorpion connection you have the steel teeth yielding instead?

C: Yes, in effect we designed a casting that absorbs all the energy, kind of like a fuse in a circuit, and the idea is that after an earthquake you could pull out the damaged component and replace it: the idea is heading towards modular construction, replaceability, and also high performance.

Scorpion Yielding Connector being tested at the University of Toronto (compression), image courtesy of CastConnex

Scorpion Yielding Connector being tested at the University of Toronto (compression), image courtesy of CastConnex

E: So you’re actually able to pull these connectors out of the building and replace them after they’ve yielded in a seismic event?

C: Yes, theoretically.

E: That’s an amazing advancement. I mean, designing a building that will remain standing after an earthquake is already captured by our design codes, but to have a building that won’t require significant repairs or even decommissioning post-disaster is rare.

M: There is still damage—it’s not a damage proof system—but designing it to be a replaceable element, provided there is not too much residual drift in the building, makes it a less painful way to repair the building and get it ready for the next earthquake.

E: Has the scorpion connector been used in practice?

C: It's been used in two buildings so far. One was used in a new building in BC, and the other was used in a retrofit of an existing high school in Saint-Paul, Quebec, which is actually Canada’s highest seismic zone.

Scorpion Yielding Connectors installed in a braced frame, image courtesy of CastConnex

Scorpion Yielding Connectors installed in a braced frame, image courtesy of CastConnex

E: Seeing as how both of you have an academic background with the University of Toronto, are you still involved with the research being done there?

M: Definitely! We actually sponsored a collaborative research program at U of T so we go back there all the time. There have been a few spinoff projects from our work as well; Professor Christopoulos is still pretty active studying castings. One ongoing project right now is looking at the actual characteristics of the cast material from a ductility perspective. I mean we designed and tested the scorpion, and my scope of work got it to the point where it works really well, but we’d like to have a complete and fundamental understanding of how the material behaves.

C: And we’ve funded some other additional research, so we’re very much connected to U of T.

E: You’ve already touched on a few of the company’s signature products, are there any other products you offer?

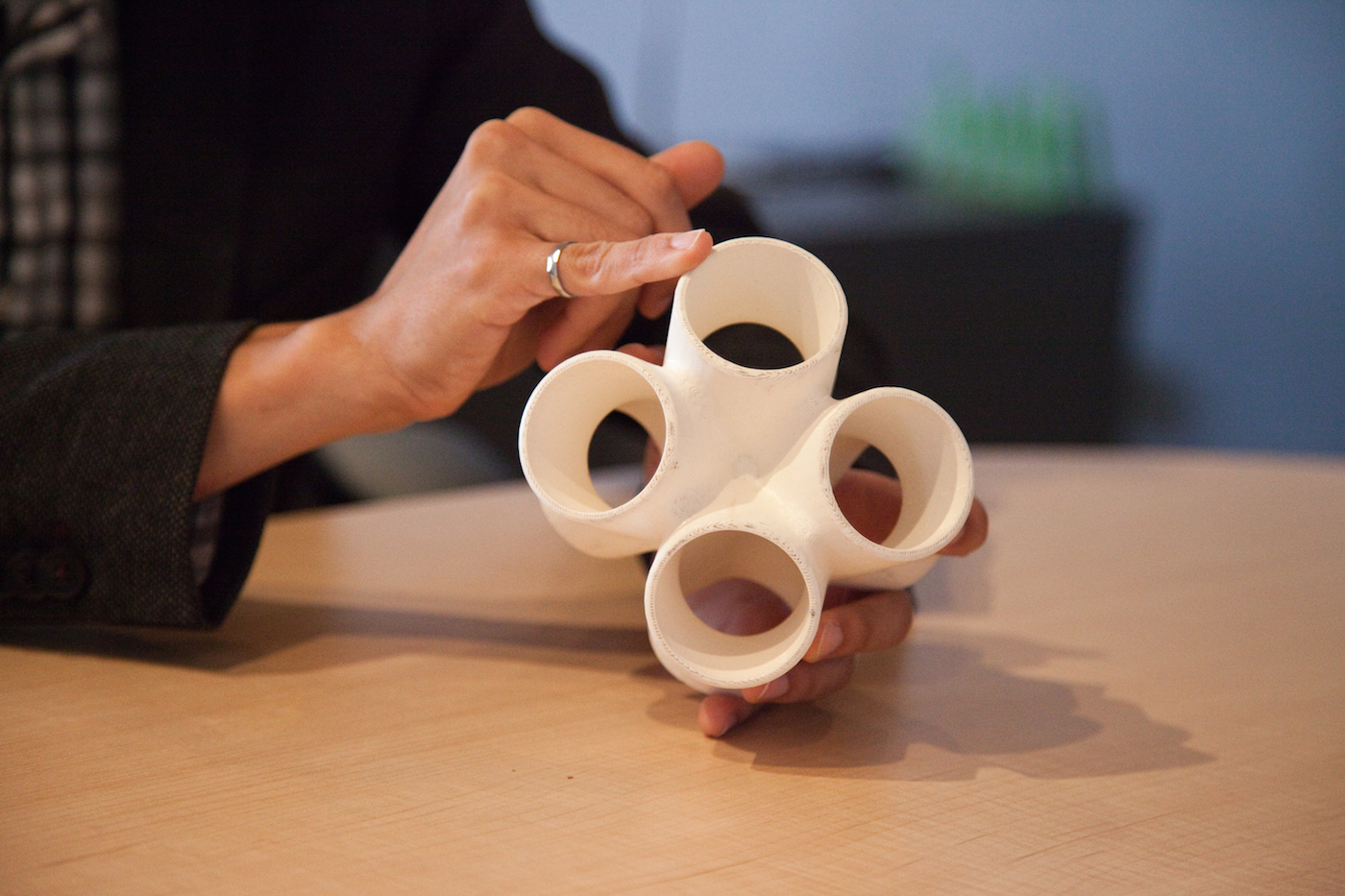

C: As we discussed, for seismic applications we have the high strength connectors I developed during my Masters, and the scorpion yielding connectors developed by Michael during his doctorate, then we have our universal pin connectors.

High Strength Connectors in a braced frame, image courtesy of CastConnex

High Strength Connectors in a braced frame, image courtesy of CastConnex

C: They are for use in architecturally exposed structural steel, like a modular version of the true pin connections you see a lot in airports and stadiums. It works on the same kind of premise; it’s very easy to fabricate and to design into a building project, but the idea is that now you can achieve the sculpted, smooth transitions that architectural expression people are looking for without the painstaking and laborious fabrication process.

Universal Pin Connection, image courtesy of CastConnex

Universal Pin Connection, image courtesy of CastConnex

E: So architecturally exposed steel is an important niche for the company?

C: We started the company based on seismic products, but we’ve now also turned our attention to architectural connections. We have another line of products for architecturally exposed structural steel as well, our architectural tapers, which you can use on their own at the tops and bottoms of columns, say, or in conjunction with our pin connectors, which makes the member look more slender overall.

E: And are all these products scalable? So the size of the connector can be increased or decreased depending on the application?

C: Yes, we have a series of different sizes available for all of the products we’ve developed. For example, the high strength connectors can get as large as this 2x1 metre table, and same with the scorpion and pin connectors.

E: That's a perfect lead-in to start talking about the Queen Richmond Centre West. UrbanToronto has been covering that project for a long time, but I was hoping you could tell us more about the specific role CastConnex played on the project.

C: Sure! So in 2009 we got a call from the engineers at Stephenson Engineering, and they said we are working on an incredible project: "we are going to be putting a building up in the air on stilts and we have a connection challenge". They had been discussing with fabricators and had come up with some ways to make it work, but they also wanted us to take a look at it as a casting. After all, we’re talking about supporting an 11-storey reinforced concrete office building up in the air, so the forces on the connection are just enormous, and on top of that it has to look good because it’s architecturally exposed and it’s in the main atrium of this building.

So we went in and met with the design team and talked to them about castings—at the time we had only made smaller castings—but I showed them numerous examples from around the world where people were using very large cast nodes; in offshore construction for example.

Queen Richmond Centre featuring one of the 3 large delta frames

Queen Richmond Centre featuring one of the 3 large delta frames

E: Was there a precedent for the recommendations you made?

C: There was a precedent in offshore and tubular construction, but not really in North America. In those cases where castings of that scale had been done, the aesthetics were not driving the design, it was basically just using castings to simplify the fabrication and to deal with the fatigue loads that are involved in offshore design.

So they liked the idea, and they thought we could do something that is obviously more elegant than could have been done with fabrication. With fabrication, the legs had to be splayed out completely from one another and there would have been a very thick steel plate between the top and bottom legs at the midpoint. You would have the four legs coming in, and you would have a very big steel plate and then the four legs above.

E: Which means if you were filling the legs with concrete you would have to do it in two separate lifts, correct?

C: Exactly. Well, you might be able to perforate that centre plate, but you keyed in on some of the construction challenges. From a structural design perspective, there were also significant challenges since these delta frames are also part of the lateral load resisting system. You can imagine when the wind blows on the tower above, that the force has to go through the delta frames in the atrium, and all you would have had is a steel plate connecting the legs through the middle of the node: all the shear force would have had to go through that plate.

So there were some construction challenges, and then there were some technical issues with using the fabricated alternative. They were looking at filling the fabricated node with shear studs since the concrete was going to creep away from the central plate: you would then get separation between the plate and the concrete, leading to 100% of the load having to go through the steel and then into the composite steel-concrete legs. There were questions about how that would work.

So the designers had all of these technical questions with the fabricated method, but at the same time they were saying “fabrication is tried, tested and true right? That’s just how you do things”. Then we waltz in and say “No, that’s not necessarily how you have to do things”.

So we basically had to answer the design team’s technical questions and put together a cost proposal for the full package of engineering design and supply of these components. Ultimately it came to a pretty stressful meeting where I presented the whole thing to the owner—Michael Emory at Allied Properties—with the architects at Sweeny &Co. At the end of the discussion, Mr. Emory had in front of him one rendering of the delta frame with the cast node and one with the fabricated option. The room went silent, and he just said, “it has to be this one” pointing at the casted option. That was how the decision was made, there were numerous other advantages to using a casting, but aesthetics were really the deciding factor.

Rendering of a delta frame in the QRC, image courtesy of CastConnex

Rendering of a delta frame in the QRC, image courtesy of CastConnex

E: What was the actual design process like?

C: After that meeting we were formally engaged on the project, and from that point on it was a really collaborative and integrated design process. We worked closely with the engineers at Stephenson—they’ve engineered the whole building, so they are worried about what forces are going into this frame—but from that point they just gave us the forces on the node and we engineered the connection.

It’s an industrial design process; the outside is shaped from an aesthetics perspective, working very closely with Sweeny &Co to establish the aesthetic and shaping of the junction, to set the various radii, how the legs come together, and how the node looks from underneath. We used rapid prototyping to study the various options; it's really an exciting process. Then we took the loads from Stephenson and worked out what the internal geometry of the node would have to be to keep the node from getting crushed under the weight and lateral forces from the tower above. For example, there is a rib on the inside that gives the node additional strength. There are also other details we build in to address constructability, like weld bevels on the lower nozzle ends, but then at the top, the connecting pipe is beveled instead so that welding in the field is predominantly downhand, which is preferred from a fabrication perspective.

Carlos showing the details of the cast node on a scale model, image by Jack Landau

Carlos showing the details of the cast node on a scale model, image by Jack Landau

E: You were working closely with the fabricator early on?

C: Yeah, the fabricator was brought onboard at the 95% CD stage in a design assist role so that they could work out the rest of the details as well. I mean, it’s a complicated steel frame: you have some very complex foundations at the base of each of the delta frames, and then you have to integrate the steel with the reinforced concrete at the tabletop level—there was a lot of complicated detailing that had to get sorted out—and Walters was brought on early at the same time we were, so all the design for the cast node was happening at the same time they were dealing with the other fabrication details. That was an ideal setup, really, as we worked very closely with Walters as well as with the owner's consultants to make the project a success.

Cast node being installed for QRC delta frame

Cast node being installed for QRC delta frame

E: From a structural analysis perspective, what software did you use to model the node?

C: For the 3D modeling software we used Solidworks and we did the finite element stress analysis in Abacus. Besides just designing the node for its end use, we also have to concern ourselves with the way this node is manufactured, so besides just shaping it on the outside for aesthetics and inside for structural loading, we have to also shape it so that it can be molded and cast. When we’re designing a casting, we have to understand how the molten steel is going to fill the mold, and then we have to understand how the molten steel is going to solidify in the mold.

E: You mean you don’t want heat pockets to form in the casting while it’s cooling?

C: Exactly. You can appreciate it’s like when you take water and freeze it to ice: it expands. The same thing happens, except backwards with steel: it contracts as it changes phase. We have to worry about how this thing solidifies—where it starts to solidify first, and where it solidifies last—because the last place to soldify is going to have a fist sized void at its centre. So we actually designed the node with surfaces where we could attach risers, which are basically just an extension of the casting that is cut off after the process. The riser is basically the location where the part solidifies last.

E: Sort of like a sacrificial layer?

C: Exactly. Additionally, we had to specify the mechanical and chemical properties of the material, as well as heat treatment. This is to make sure that the casting has the structural properties required by the application. So when I said this was an industrial design process, you can see that it really is: we’re not just looking at the final purpose, instead we are designing so that it can actually be manufactured as a casting. Then of course making sure the casting can be incorporated into conventionally fabricated structural steel assembly.

At the end of the day we delivered these castings to Walters who had to work with them, so if they can’t weld to them, the buck stops with us so to speak.

E: At the end of the day, what sort of savings or benefits was CastConnex able to bring to the project by providing the cast codes for the delta frames?

C: The obvious thing is aesthetics—you go into that atrium and you see what looks like a monolithic support structure, and if you’re familiar with construction you just go “wow, how did they even do that?” It’s pretty amazing! How does one quantify that in dollars?

From a fabrication perspective, just looking at the cost to fabricate—assuming you could have solved all those technical challenges we discussed earlier—our cast nodes were more expensive, but there were other savings afforded by using cast nodes. The fact that when the cast nodes are installed the delta frames become much stiffer means that the frames themselves provide so much more stiffness to the lateral system; therefore the reinforced concrete elevator core requires less concrete and rebar. This wasn’t quantified all that closely, since the decision was made on aesthetic principles, but there were a lot of peripheral savings in using castings that, on the net, very likely led to project savings, but a lot of those savings weren’t understood until we modeled the whole structure, with the cast node in place of the fabricated node, in Stephenson’s ETABS model of the tower.

The 'wow' factor is seeing the delta frames completed from inside the atrium, image by Craig White

The 'wow' factor is seeing the delta frames completed from inside the atrium, image by Craig White

E: So would you say working on QRC West was a learning process for the company?

C: We had done it lots of times for smaller castings—this was the first time we did it on something this big—but since then we’ve done it a whole bunch of times, and even bigger.

E: Bigger? For what project?!

C: For the Transbay Transit Center, in San Francisco. So QRC West is incredibly unique from an architectural and structural design perspective, but Transbay from a castings perspective is like that building on hyper-steroids. There were 400 castings; the smallest castings are 4,500 pounds and the largest are 45,000 pounds. For comparison the QRC West node was 35,000 pounds. The castings in Transbay are used in two locations; first in the perimeter structure, which is an architecturally exposed frame and is also the building’s seismic force resisting system—like an exoskeleton—then the other castings on the project are in the 150 foot tall light column. So the Transit Center has three above-grade and three below-grade levels, and there is an elliptically-shaped light tunnel that goes right down into the basement which lets natural into the lower levels. The light column is all created as architecturally exposed structural steel, and it also supports some of the building's gravity loading as well, so that steel frame is really heavy and there are a variety of cast nodes in it.

E: This seems like a much more involved project from CastConnex’s perspective.

C: It's a very complex structure. In this project, CastConnex didn’t supply the castings. We were engaged by the Transbay Joint Powers Authority and we worked with them, assisting their structural engineer of record, Thornton Tomasetti, and the architects at Pelli Clark Pelli and Adamson Associates to put castings into the project. Then we oversaw the manufacturing of the nodes.

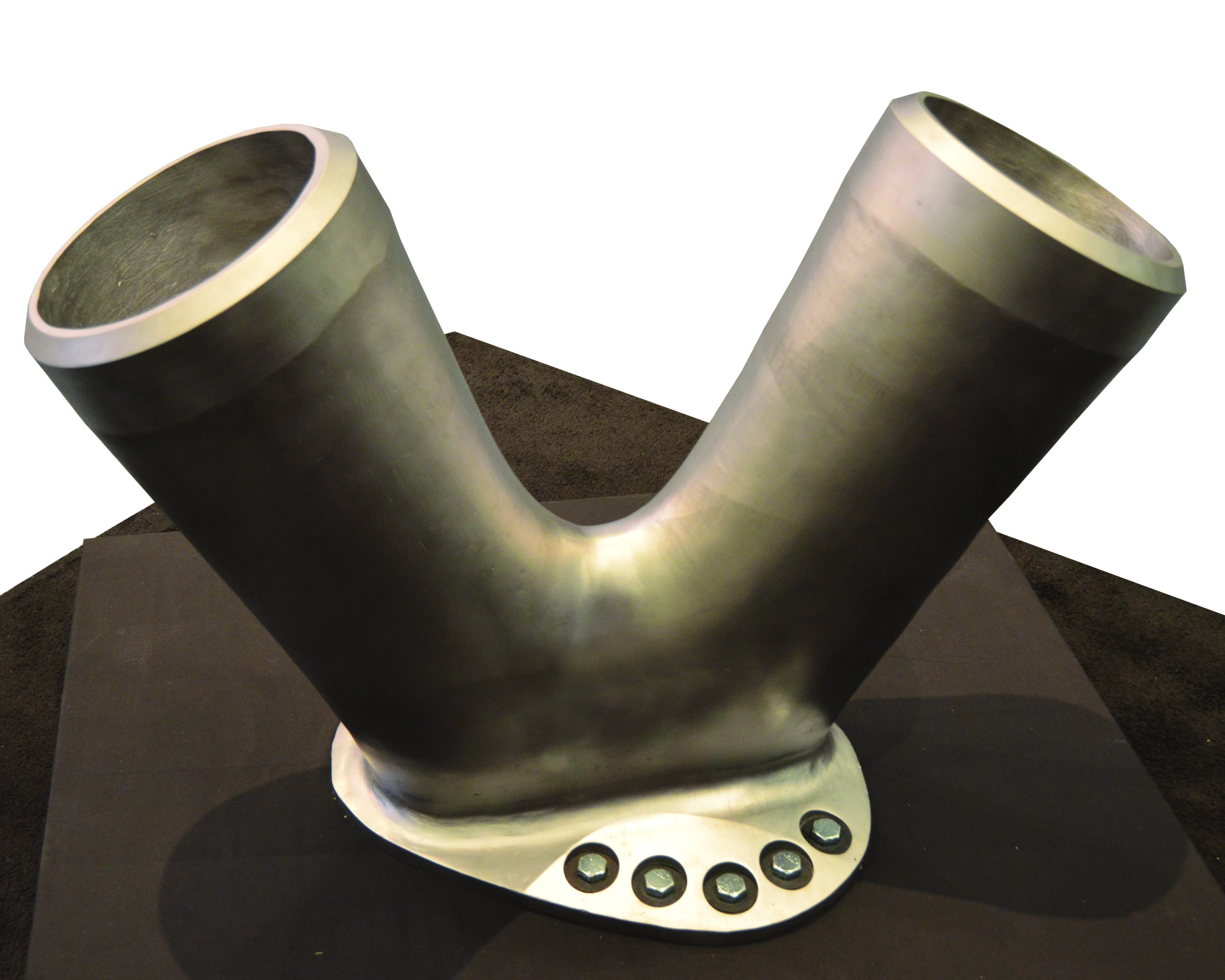

E: So what does the future hold for CastConnex and are there any interesting projects on the horizon? Anything else in Toronto?

C: We have a casting that is actually being put into the Pioneer Village [subway and] bus station designed by IBI Group with Will Alsop. This is just a one off, making one casting for the V-column base right at the entrance. People will see it when they walk from the bus terminal to the subway station.

Pioneer Village bus terminal casting, image courtesy of CastConnex

Pioneer Village bus terminal casting, image courtesy of CastConnex

E: Is the company planning to expand its operations?

C: We recently opened up an office in San Francisco, and now we’re looking at opening an office in New York City.

E: I’m assuming the office in San Francisco will be capturing some of the seismic design work in California?

M: Sure, and if you think about it, California is the same size population-wise as all of Canada; it’s just a bigger market.

C: We opened up that office about a year and a half ago and it’s been very successful. We’re moving on by opening up this office in New York City, which will be more focused on architecturally exposed structural steel. We’ve already been involved in World Trade Center Tower 3, and also for Arthur Ashe Stadium where they are putting in a new retractable roof. Then our pin connectors were used in the Whitney Museum of American Art, designed by Renzo Piano. Basically there is work in New York, and by opening up this office we just want to grab on to it, and in general we’ve just done a lot of work in the Northeastern US.

E: I want to thank you both for taking the time to sit down with UrbanToronto - I know our readers are going to really appreciate all this technical insight you have provided on both QRC West, and in castings in general. Good luck with all future endeavours, and please keep us posted on any new projects CastConnex is involved in!

Carlos (left) and Micheal, the co-founders of CastConnex, standing beside a scorpion yielding connector, image by Jack Landau

Carlos (left) and Micheal, the co-founders of CastConnex, standing beside a scorpion yielding connector, image by Jack Landau

| Related Companies: | Eastern Construction, Kramer Design Associates Limited, Sweeny &Co Architects Inc., Trillium Architectural Products |

2.7K

2.7K