Benito

Senior Member

Today.

Yes, exactly! If you have ever poured concrete yourself, you can feel the heat the concrete emits as it cures. Not to mention, given the size of these columns, they will be curing (gaining in compressive strength) for months potentially. I recall a project where the concrete on 1 section of a slab pour, took 45 days to reach its minimum required bearing capacity.Well these are massive thick pours, meaning they generate tons of heat and evaporate water.

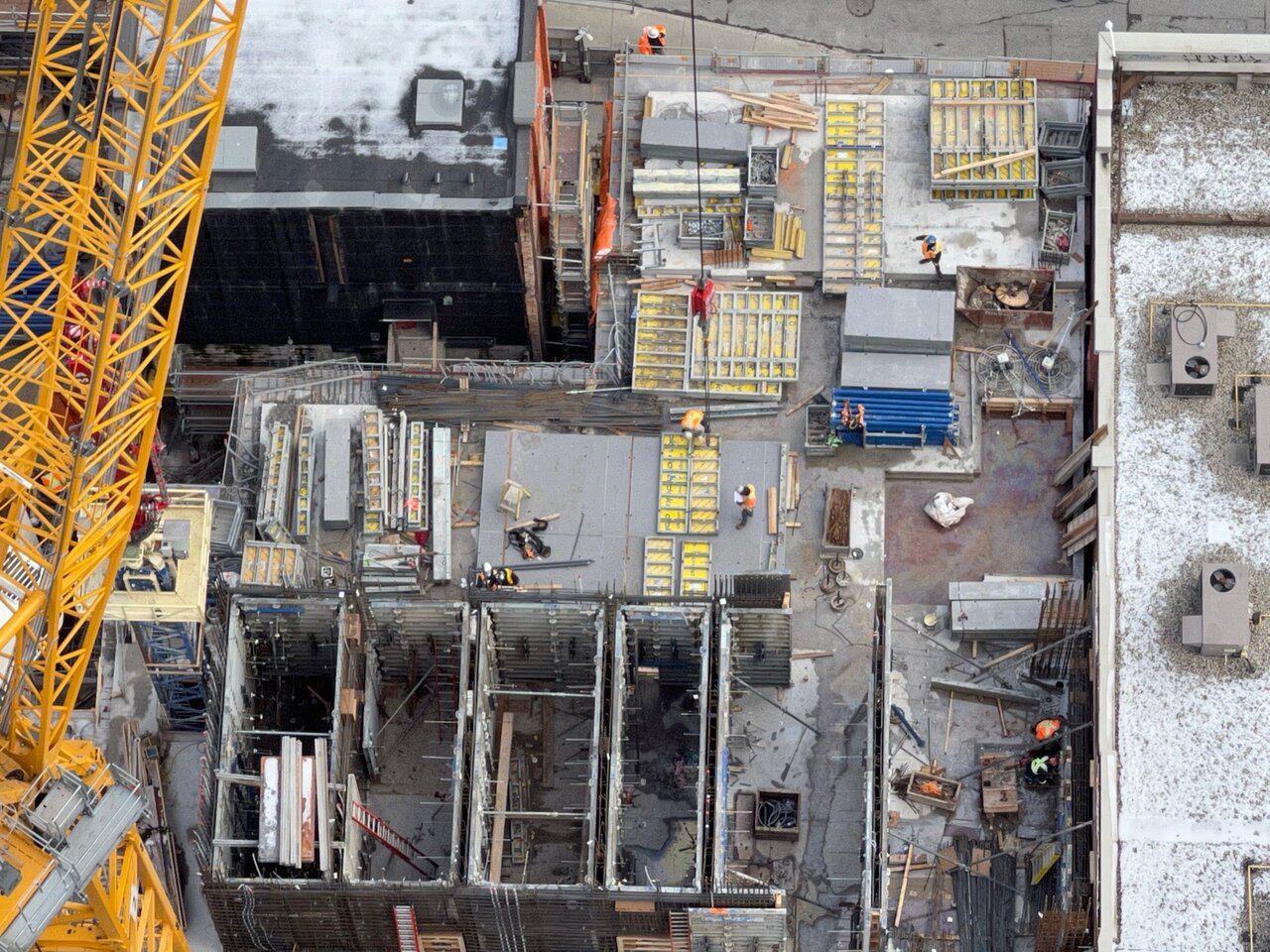

One would think a 308 metre-tall building with no central elevator core going all the way to the foundations would be more of a walk in the park.Looking at the recent photos, I am taken aback by the amount of complexity at the site.

Here are 2 pictures I took today. Not sure if it's anything to worry about but most certainly, there are cracks.How are you able to see a hairline crack? Are you able to get in there up close?

Those 'cracks' are completely normal for something like this. Nothing to get worked up over.Here are 2 pictures I took today. Not sure if it's anything to worry about but most certainly, there are cracks.

Maybe a forum member who lives or works in the area can try to snap some photos of a different column to see if, in fact, they did do better.I would say over watered concrete for a complex thick pour, nothing that would be a major issue but they can do better